Services

Services

In addition to injection and blow molding, Almega Plastics is able to provide services to support your business. From closure lining, assembly, filling, mold maintenance, and more.

Closure Lining, Component Assembly, and Filling

Almega Plastics is able to provide the complete package for your specific application. To do so we offer a wide range of services to accompany our injection and extrusion blow molding capabilities.

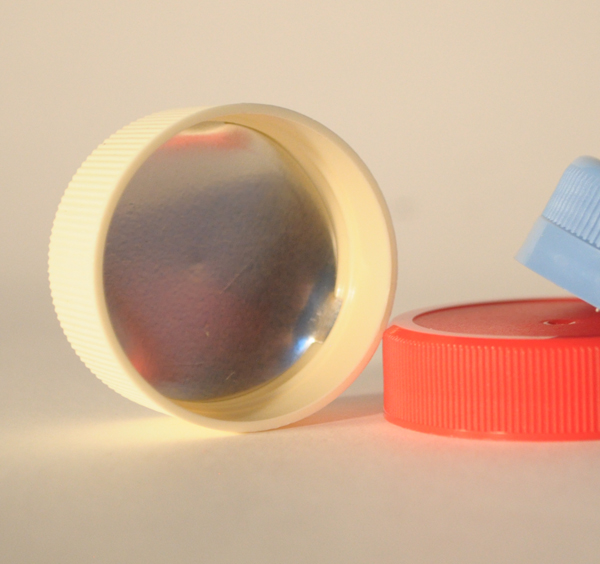

Closure Lining

Our facility is able to accommodate a wide range of closure lining materials, such as induction, foam, and foil.

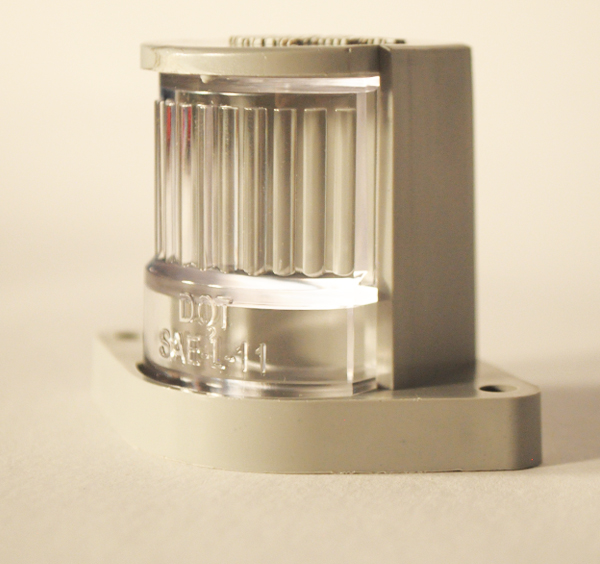

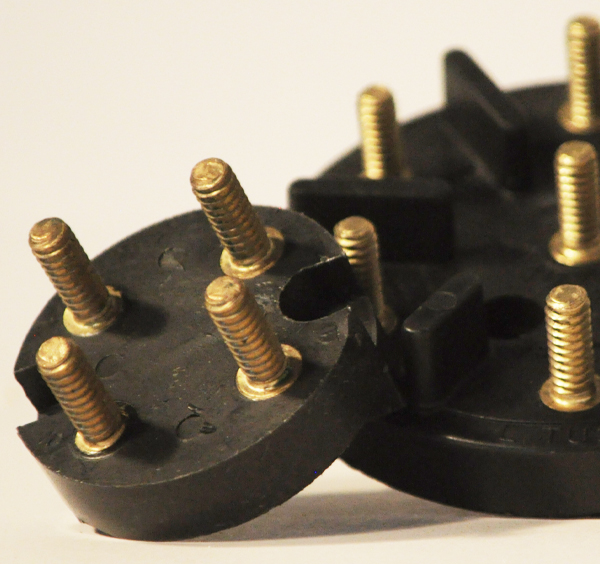

Assembly

As a best-in-class manufacturer of quality molded components, we are able to provide custom-tailored assembly services and ship you a completed product.

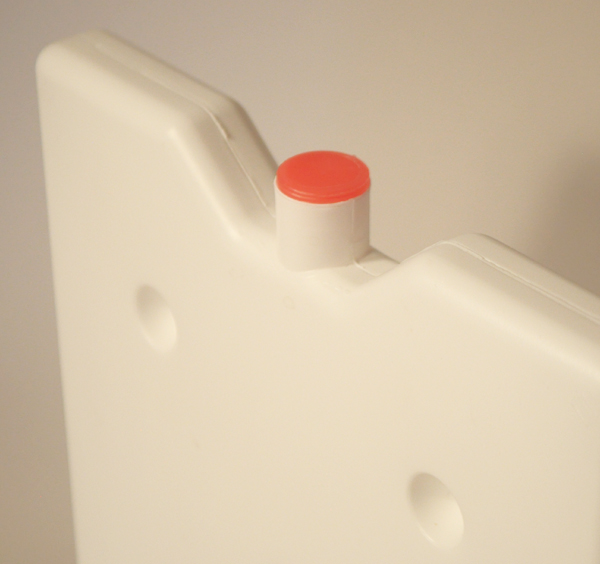

Filling

Our manufacturing facility has the ability to provide filling services. We are able to handle several different types of materials and closure systems to produce a final product.

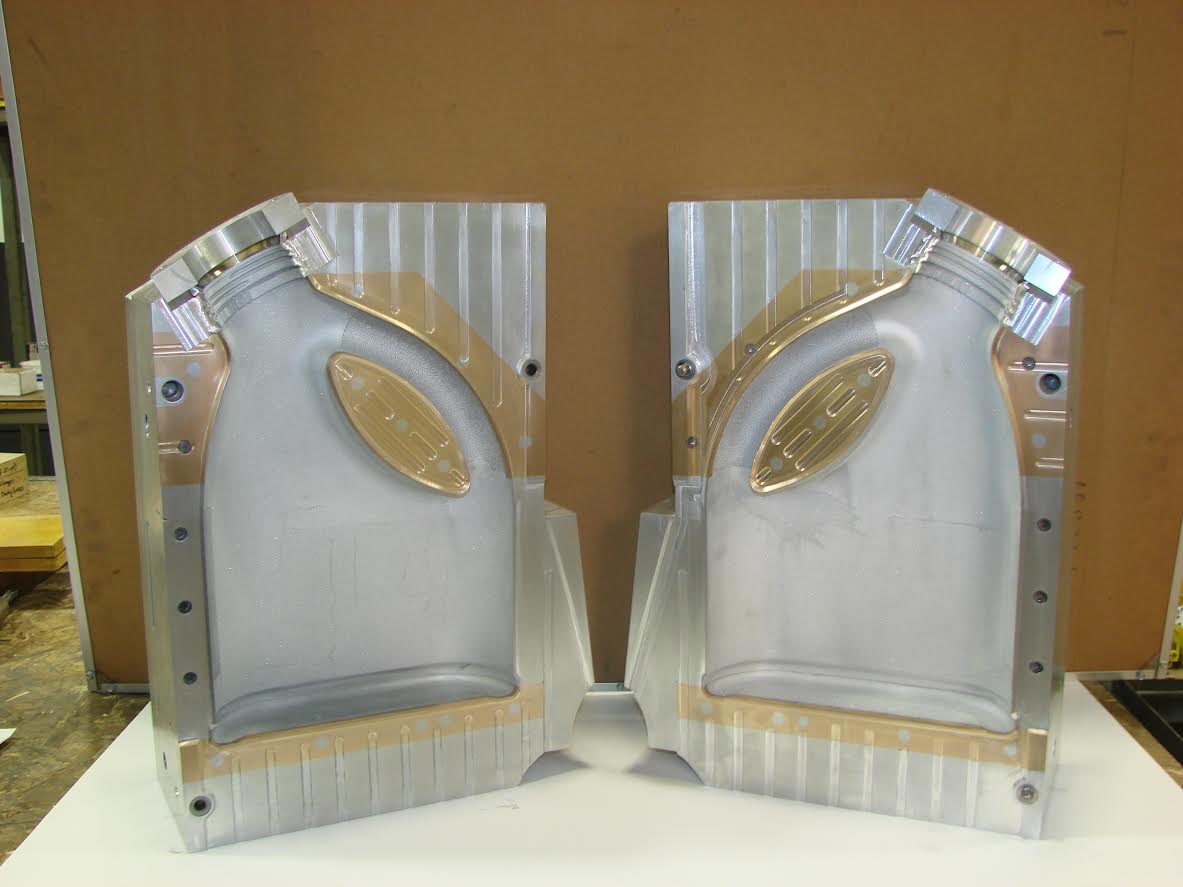

Examples of various service capabilities

Onsite Mold Maintenance Facility

When you entrust Almega Plastics with your injection or extrusion blow mold, you can rest assured that we have qualified and experienced experts running, storing, and handling your tools.

Our facility is equipped with an onsite mold maintenance shop. We have the ability to provide tool maintenance to ensure that when it is running it will continue to produce the highest quality components.

Quality Assurance Capabilities

Quality comes standard at Almega Plastics. Our dedicated quality assurance team will inspect and ensure that the produced components meet your highest specification.

Additionally, our QA/QC team is able to provide you with the required documentation on the various production runs for your components to ensure compliance.

Custom Mold Design and Manufacturing Services

In some cases, it may be required to design and manufacture a tool for your specific application. Almega is experienced in providing turn-key package and component design services. We also have the ability to produce single-unit tools, as well as the full production tool to scale with your product development process.